Animals, Agriculture & Food

Improved Methods for Producing Low-Cost Protein-Polysaccharide Conjugates for Use in Foods and Beverages

WARF: P08190US

Inventors: John Lucey, Dani Zhu, Srinivasan Damodaran

The Wisconsin Alumni Research Foundation (WARF) is seeking commercial partners interested in developing an improved wet heating technique for producing protein-polysaccharide conjugates, which provide a less expensive alternative to gum Arabic in foods and beverages. Conjugation of proteins greatly improves their functional properties without requiring the use of chemicals or cross-linking enzymes.

Overview

Protein-polysaccharide conjugates (PPCs) are useful as emulsifiers in foods and beverages. Because the polysaccharide stabilizes the protein, such conjugates have superior functional properties, including gelation, emulsification, solubility and stability, as compared to unaltered proteins.

A naturally produced PPC is found in gum Arabic, which is used extensively in foods and beverages. However, the price and availability of gum Arabic varies widely, due to issues with growth and harvest as well as regional troubles.

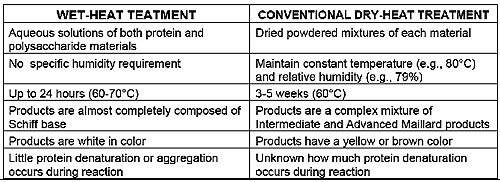

Current research techniques for producing PPCs are based on dry heating methods. However, these techniques have several drawbacks, including the formation of undesirable byproducts and requirement for long holding times at high temperature and humidity, which make them impractical for commercial use. A new approach for the production of PPCs is needed.

A naturally produced PPC is found in gum Arabic, which is used extensively in foods and beverages. However, the price and availability of gum Arabic varies widely, due to issues with growth and harvest as well as regional troubles.

Current research techniques for producing PPCs are based on dry heating methods. However, these techniques have several drawbacks, including the formation of undesirable byproducts and requirement for long holding times at high temperature and humidity, which make them impractical for commercial use. A new approach for the production of PPCs is needed.

The Invention

UW–Madison researchers have developed novel methods of producing protein-polysaccharide complexes using a wet heat treatment. The process involves heating aqueous solutions containing protein in the presence of a polysaccharide with a reducing sugar. High concentrations of a stabilizing polysaccharide, such as dextran, are used to prevent unwanted protein denaturation. The resulting PPCs exhibit improved thermal stability, more desirable color and excellent emulsifying properties. They are superior to both unmodified protein and gum Arabic.

Applications

- Production of PPCs for use as emulsifiers in foods and beverages

- Potentially useful to reduce the allergenicity of proteins for the manufacture of infant formula

- Can be used to attach biologically important carbohydrates to proteins for nutritional or bioactivity purposes

Key Benefits

- Provides a less expensive substitute for gum Arabic

- Requires much less time and energy than the dry heating method

- Produces PPCs with superior properties, including improved thermal stability, color and emulsifying properties

- Does not require purification–for some applications, the entire mixture may be used as a food ingredient

- Offers improved protection against protein aggregation

- Allows use of higher treatment temperatures than dry heating techniques

- Avoids formation of undesirable byproducts

- Uses a molecular crowding effect that improves efficiency of the conjugation reaction

- May alleviate astringency of proteins, for example in protein-fortified acid beverages

Stage of Development

The development of this technology was supported by WARF Accelerator. WARF Accelerator selects WARF's most commercially promising technologies and provides expert assistance and funding to enable achievement of commercially significant milestones. WARF believes that these technologies are especially attractive opportunities for licensing.

Additional Information

For More Information About the Inventors

Publications

- Zhu D., Damodaran S. and Lucey J.A. 2008. Formation of Whey Protein Isolate (WPI)-Dextran Conjugates in Aqueous Solutions. J. Agric. Food Chem. 56, 7113–7118.

- Zhu D., Damodaran S. and Lucey J.A. 2010. Physicochemical and Emulsifying Properties of Whey Protein Isolate (WPI)-Dextran Conjugates Produced in Aqueous Solution. J. Agric. Food Chem. 58, 2988–2994.

Tech Fields

For current licensing status, please contact Mark Staudt at [javascript protected email address] or 608-960-9845

Figures